ERP and sustainability: How a system can reduce environmental impact

Sustainability has become a crucial priority in today’s business landscape. From government policies imposing stricter regulations to consumer expectations of environmentally responsible brands, businesses must adapt and make strategic decisions geared towards sustainability. In this context, Enterprise Resource Planning (ERP) systems have emerged as a key tool to improve operational efficiency and reduce the environmental impact of organisations. These systems integrate the different areas of the company and allow for a more efficient management of resources, reducing both waste and the ecological footprint.

- Why sustainability is key in today's business environment

- The role of ERP systems in sustainable transformation

- What is an ERP and how does it influence sustainability?

- Sustainable benefits of implementing ERP in companies

- Case studies: Companies that applied ERP to be more sustainable

- Challenges and considerations when implementing sustainable ERP

- Future of ERP in sustainability: Trends and emerging technology

- Conclusion

Why sustainability is key in today’s business environment

Sustainability has been transformed from a peripheral concept to a core business strategy, essential not only to improve corporate image, but also to optimise processes and reduce costs. As governments tighten environmental regulations and consumers demand transparency in business practices, companies must incorporate green approaches into their operations. Sustainability also has a direct impact on long-term financial results, as more sustainable operations tend to reduce costs, improve energy efficiency and minimise waste, which positively impacts profits.

Sustainability Report 2023 McKinsey & Company’s Corporate highlights that companies that adopt more sustainable practices are 20% more likely to achieve better financial returns due to reduced operating costs, increased efficiency and consumer loyalty. This reinforces the need to integrate sustainability into the core strategy of any business.

The role of ERP systems in sustainable transformation

ERP systems are fundamental in this process of transformation towards sustainability. An ERP helps companies to optimise their operations through the digitisation and automation of processes, which reduces human error, resource use and waste generation. By integrating key areas such as production, logistics, inventory control and financial management, ERPs allow companies to gain a holistic view of their operations and assess the environmental impact of each activity in real time.

What is an ERP and how does it influence sustainability?

Defining an ERP: Efficient enterprise resource management

An ERP system is a set of software applications that centralise and manage the main business processes within an organisation. These platforms allow finance, human resources, inventory, sales and production departments to work in a coordinated manner and share information efficiently. The main objective is to optimise the management of business resources and improve decision-making by automating processes and integrating information.

From a sustainability perspective, an ERP offers much more precise control over the natural and material resources used in a company’s operations. By monitoring energy and material consumption in real time, ERPs facilitate the identification of areas that require improvement to make more rational use of resources. The main objective is to optimise the management of business resources and improve decision-making by automating processes and integrating information.

How ERP optimises resources and reduces waste

ERP systems optimise the use of resources and minimise waste at various levels. For example, in inventory management, an ERP allows to adjust purchasing and production according to actual market needs, avoiding both overstocking and shortages. By integrating all data on a single platform, companies can forecast material needs more accurately and avoid overproduction, which can result in wasted resources and energy.

Automating processes to minimise paper use

Process automation is one of the most effective ways in which ERP contributes to sustainability. Many business processes, such as invoicing, purchase order approval and reporting, traditionally relied on a large number of paper documents. With an ERP, this entire workflow is digitised, reducing the need to print, store and transport physical documents, thereby reducing paper consumption and associated costs.

Energy management and control with ERP modules

Energy consumption is another major area of optimisation for companies seeking to become more sustainable. Some ERP systems offer specific modules for energy monitoring and management. These modules allow companies to identify inefficient consumption patterns, adjust energy use in real time and conduct energy audits. With this information, companies can make informed decisions to reduce energy consumption and improve their energy efficiency.

Sustainable benefits of implementing ERP in companies

Reducing the corporate carbon footprint

One of the most direct benefits of an ERP in terms of sustainability is the reduction of the carbon footprint. By optimising production, logistics and supply chain processes, companies can significantly reduce greenhouse gas emissions. For example, ERP can optimise transport routes, reduce machine running time and better control the waste generated, which reduces the company’s overall carbon footprint.

Efficient supply chain management and emissions reduction

How ERP improves logistics and minimises travel

Logistics is one of the areas where ERP can have the greatest impact on sustainability. By integrating the different stages of the supply chain, ERP enables companies to optimise route planning and vehicle use, which can reduce emissions generated by transport. In addition, by efficiently managing inventories, ERP helps to avoid overproduction and reduce the number of unnecessary trips.

Optimisation of the use of material and energy resources

ERP enables more efficient management of material and energy resources by providing real-time visibility of their consumption and use. This not only improves production efficiency, but also reduces costs associated with waste and overuse of resources. For example, by monitoring energy consumption in real time, companies can adjust operations to reduce energy demand during peak hours.

Data analysis for more sustainable decisions

Data analytics is a key feature of ERP systems that helps companies make more sustainable decisions. By integrating data on material, energy and emissions consumption, ERP enables organisations to identify areas for improvement and make informed decisions to make their operations greener. For example, energy consumption data can help identify the most inefficient facilities and implement measures to improve their energy performance.

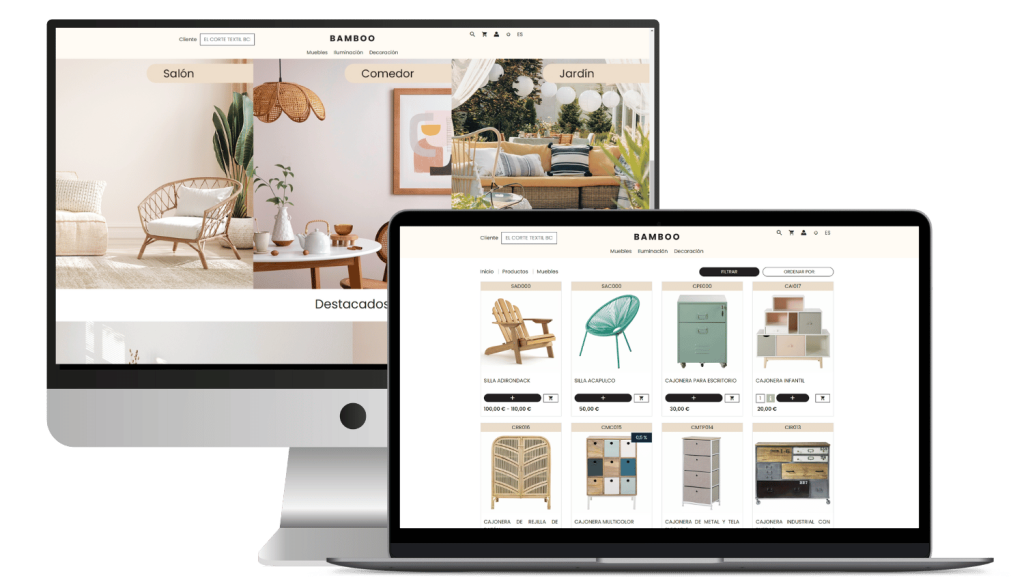

Transform your ERP into a powerful B2B ecommerce system

Case studies: Companies that applied ERP to be more sustainable

Example 1: Manufacturing industry

BMW is a prime example of how ERP can help a company reduce its environmental impact. The German carmaker has implemented an ERP system to manage its production processes, optimise logistics and control energy consumption. Thanks to this implementation, BMW has managed to reduce its CO₂ emissions by 25% over the past two decades, demonstrating that ERP can be an effective tool for sustainability in the manufacturing industry.

Example 2: Retail sector

H&M has used ERP to manage its supply chain and improve the sustainability of its operations. With this system, the company has optimised inventory management, improved logistics, and ensured that its materials and products come from sustainable sources. The transparency of data obtained through ERP has also enabled them to improve their communication with consumers about their green practices.

Example 3: Logistics and transport

DHL is another example of how ERP systems contribute to sustainability. The company has integrated an ERP system to improve the efficiency of its supply chain and logistics. This has enabled them to optimise transport routes, reduce CO₂ emissions and improve energy efficiency in their logistics operations.

Challenges and considerations when implementing sustainable ERP

Initial costs vs. long-term benefits

One of the biggest challenges of implementing a sustainable ERP is the initial cost. These systems can require significant investment, both in software purchase and staff training. However, the long-term benefits, such as reduced operating costs, improved energy efficiency and reduced carbon footprint, far outweigh the initial investment.

Cultural and organisational barriers

The implementation of sustainable ERP can also be hindered by cultural barriers within the organisation. Resistance to change and lack of technology skills are common obstacles. Companies must address these barriers through ongoing training, effective communication and the integration of sustainability into the organisational culture.

Selecting the right ERP to maximise sustainable impact

Not all ERP systems are equally effective in terms of sustainability. It is crucial to select an ERP that offers specific modules for energy management, emissions monitoring and resource optimisation. It should also be a flexible and scalable system that can adapt to the changing needs of the business as it grows and evolves.

Future of ERP in sustainability: Trends and emerging technology

Integrating IoT and Big Data into ERP systems

In the future, the integration of emerging technologies such as the Internet of Things (IoT) and Big Data promises to further transform ERP systems, enhancing their ability to support sustainability. IoT devices, such as smart sensors, enable real-time data collection on various aspects of business operations, such as energy consumption, greenhouse gas emissions, and material usage. These devices offer a much greater level of detail and accuracy, enabling even finer optimisation of resources and rapid response to any anomalies.

For example, in the case of a production plant, IoT sensors can monitor the energy efficiency of machines, automatically adjusting their operation as needed, avoiding waste. The data generated is integrated into the ERP system, allowing detailed, real-time analysis. Big Data, on the other hand, makes it possible to analyse large volumes of data and detect consumption and emissions patterns that might otherwise go unnoticed. This integration not only optimises the use of resources, but also helps companies make more informed, data-driven decisions, which can substantially improve long-term sustainability.

ERP and circular economy: A promising synergy

The circular economy, which promotes recycling and reuse of materials, is another area where ERP systems can play an important role. Rather than following the traditional linear ‘take, make, dispose’ model, companies that adopt circular economy principles seek to minimise waste by recycling and reusing resources in their operations. ERP systems can facilitate this process by providing clear visibility on the flow of materials within the company and between its suppliers and customers.

For example, an ERP can track end-of-life products, helping companies identify opportunities to reuse or recycle materials. In addition, they can optimise the recycling process by providing detailed data on the quantity and type of materials to be processed, reducing the consumption of new resources and the amount of waste sent to landfill.

The combination of ERP with a circular economy approach could revolutionise the way companies manage their supply chain and product life cycle, allowing them not only to reduce their environmental impact, but also to generate new business models based on the reuse of products and materials.

The role of artificial intelligence (AI) in sustainability

Another emerging component is the use of artificial intelligence (AI) to predict and improve sustainable practices within an ERP system. AI can analyse large volumes of data even faster and more accurately, providing predictions about consumption behaviour, product demand and energy efficiency. For example, AI can predict peaks in demand for certain products or raw materials and automatically adjust production to avoid overconsumption of resources or waste generation.

In addition, AI integrated into ERPs can help companies identify inefficient consumption patterns, propose solutions to reduce costs and improve energy efficiency, and, most importantly, predict the environmental impact of different business decisions before they are made.

Conclusion

The future of ERP systems is intrinsically linked to sustainability, and their ability to integrate emerging technologies such as IoT, Big Data and artificial intelligence will enable businesses to better manage their resources, optimise their processes and significantly reduce their environmental impact. As businesses adopt greener and more efficiency-based approaches, ERP will continue to evolve to offer even more innovative and effective solutions to support long-term sustainability.

The integration of these emerging technologies will not only bring environmental benefits, but will also create new business opportunities for companies that take advantage of them. With proper implementation and a focus on sustainability, ERP systems can become an indispensable tool for the companies of the future that seek to balance economic growth with environmental responsibility.

Share:

Related Articles

What is a marketplace? Find out how to get the most out of it

What is a marketplace? Find out how to get the most out of it In today’s digital world, marketplaces have

Business to consumer (B2C): how it works and how it differs from B2B

Business to consumer (B2C): how it works and how it differs from B2B In today’s world, e-commerce and direct business-to-consumer

Alibaba revolutionises B2B commerce with ‘Accio’ – the AI-powered search engine for SMEs

Alibaba revolutionises B2B commerce with ‘Accio’ – the AI-powered search engine for SMEs Share: Tabla de contenidos What is Accio

Examples of market segmentation: How to apply it in different sectors?

Examples of market segmentation: How to apply it in different sectors? In today’s competitive business landscape, market segmentation is more

Omni-channel strategy: How to integrate all channels to improve customer experience

Omni-channel strategy: How to integrate all channels to improve customer experience In a world where consumers use multiple channels to

What are open APIs and their role in SaaS solutions?

What are open APIs and their role in SaaS solutions? Open APIs have transformed the way businesses use software, especially

Analysis of B2B marketplaces: Are they an opportunity or a threat?

Analysis of B2B marketplaces: Are they an opportunity or a threat? B2B marketplaces are transforming the way companies buy and

How to use chatbots in B2B ecommerce to improve conversions

How to use chatbots in B2B ecommerce to improve conversions In the world of ecommerce B2B (Business to Business)shopper expectations

Customer journey in B2B: How to optimize the enterprise customer experience

Customer journey in B2B: How to optimize the enterprise customer experience Understanding the B2B customer journey is essential to optimize

Automate orders with Stoam SaaS b2b ecommerce